Haiti FabLab Fund Pecha Kucha

March 3rd, 2010Tags: earthquake, fablab, haiti, human, pecha kucha, port-au-prince, prosthetics

The haitifablab.org site is most kindly hosted by the inestimable Marco Wessel!

Years before the recent earthquake in Haiti, there was talk about putting a fablab in Port-au-Prince. There has never really been enough critical mass to start a Haitian fablab though. After the earthquake, with so much attention focused on Haiti, it was a good time to ramp up the work on a Haitian fablab. I started a website detailing the possibilities of a Fablab, seeking stakeholders for a Fablab and raising funds for a Fablab.

Based on my experiences with the Fablab in Boston and beyond, I gave a Pecha Kucha talk at the 15th Boston Pecha Kucha: the format was 20 slides, 20 seconds per slide. It was very stressful, but since I made notes beforehand, it’s easy for me to put the condensed talk online. I reposted it here, for your enjoyment.

Hi, I’m Nadya Peek, I’m a student in this building in the Physics and Media group, involved with Fablabs and the Developing World Prosthetics class in D-lab.

In this photo you can see the materials for a fablab arriving at the College of India, Pune, Maharastra. Fablabs don’t always arrive in truckloads, each Fablab is built in a different way.

a Fablab contains, amongst other things, a 3 axis router, a small 3 axis mill, a laser cutter, a vinyl cutter and a full electronics workbench. The idea is that with a Fablab, you can make almost anything- furniture, electronics, prosthetics.

the Fablab in Pune took us 5 days to set up, and that was because there was no wiring, plumbing or floor when we showed up. We set up the large 3 axis mill first, and used that to make furniture to put the rest of the stuff on.

There are more than 30 labs around the world, sometimes it can be hard to set one up, sometimes it can be easy. This picture shows the mobile Fablab, which drives around the US and is currently in Ohio. It can be self powered, and although it is easier to set up, it’s much harder to take down or away– people rarely want to give it up!

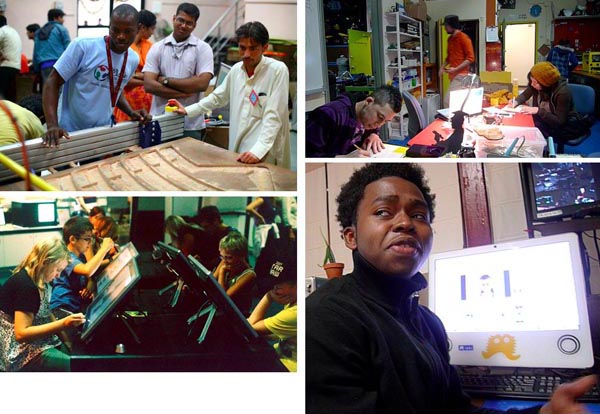

A Fablab is not only machines though, and the machines are certainly less important than the people who help run them. Here you see us at the last Fablab conference, where people from Fablabs around the world showed up to teach each other how to make things.

Each lab is in a different place and will focus on different things. North American Fablabs are generally part of community centres and educational spaces. Here on the right you see AS220 in Providence, RI, they generally have a younger crowd of high school students working on computer and engineering skills.

These are images from the CabFabLab in the Hague, the Netherlands, where girls spent a day making customised keychains on the laser cutter. The event was part of a teach a girl about engineering program.

these images are from a Fablab in Soshangove, South Africa, where this girl learned how to connect and program all kinds of input and output devices to AVR microcontrollers. She now knows more about practical electrical engineering than many electrical engineering concentrators at MIT!

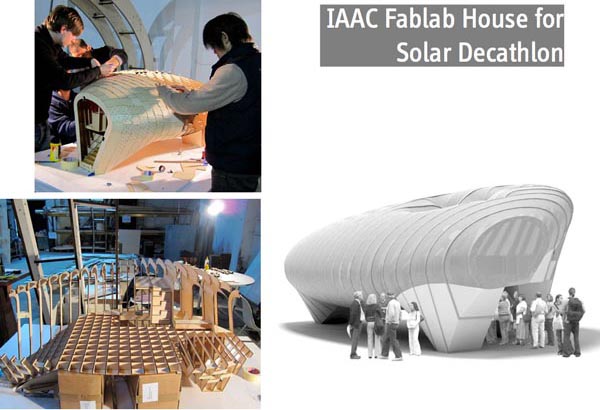

The Fablab can also be used for larger things. Here is a project by Larry Sass, a disaster response house made entirely on a Shopbot 3-axis mill and friction fit together using rubber mallets.

This Shopbotted structure is a current contender for this years Solar Decathlon in Europe.

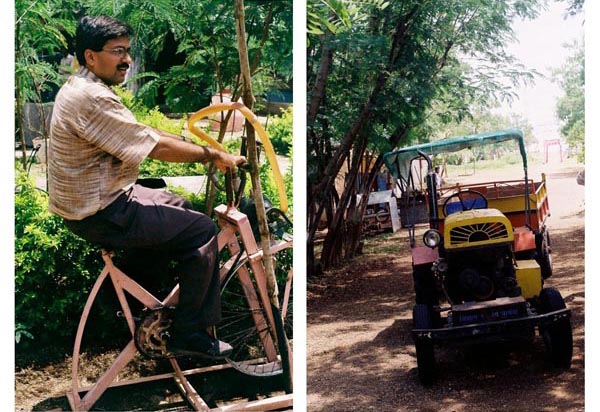

The oldest Fablab is in Pabel, India, and focusses on agricultural education. Here you can see Yogesh Kulkarni with biofuel cells and a biofuel composter.

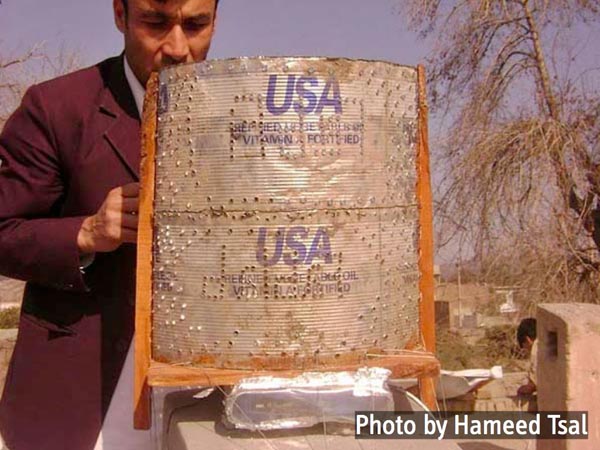

Here you see Kipp Bradford from the board of directors of the Providence based AS220 lab testing the Vigyan Ashram lab’s solar cooker (and learning that hot things are hot).

A cycle powered drip irrigator and a 2000 dollar tractor!

And here Bamboo greenhouse– none of these projects are based on the Fablab, but the Fablab houses the tools that help make them.

These are photos I took this summer at the Jaipur Foot Organisation. I’m currently working with them and a team of MIT undergrads as part of d-lab’s Developing World Prosthetics class.

We have funding from MISTI to explore rapid prototyping possibilities for prosthetics. We are currently working on children’s prosthetics in particular.

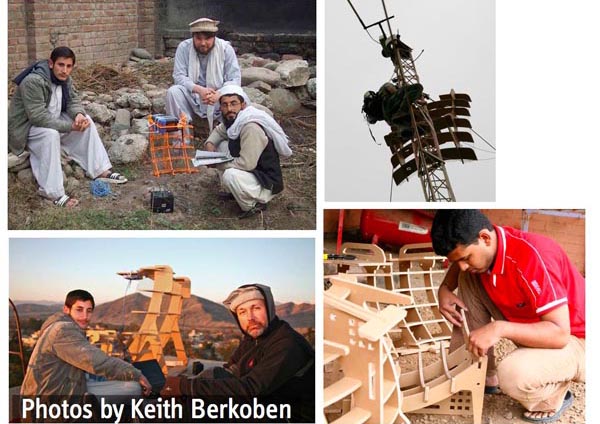

Fabfi is a project that originated in the Fablab Jalalabad, Afghanistan. There is one big satellite downlink, but not a lcoal infrastructure to get the internet around. So they designed these directional antennas for linksys routers to beam internet around to the places they needed it.

Keith Berkoben showed the routers to people in India and Afghanistan and now they are all able to make these en mass on their own.

After they got annoyed with material and the design, they were able to make their own antenna with the same basic principles and unsaid oil cans! Their antenna was only a few dBs off from the original design.

There’s been we’ve been talking a lot with different people who can be stakeholders for a Fablab in Haiti. Without people to support it, the machines in the Fablab are useless. We started a blog about our efforts and accepting donations for the Fablab.