Saudi Arabia, 3D printing and the internet of things

January 22nd, 2011Tags: 3d printer, 3d printing, abs, desktop revolution, extrusion, fablab, internet of things, jeddah, makerbot, pla, printing, reprap, saudi arabia

Warning: this is a very long post. Probably because I’m supposed to be doing a p-set.

In lulls in the marathon that is getting your PhD at MIT, I travel around the world installing fablabs. This January’s ‘Independent Activities Period’ was no different: I went to Saudi Arabia, to install the first in a series of middle eastern fablabs in Jeddah, 50 km from Mecca (no use though, non-muslims may not enter Mecca).

Unfortunately, Saudi Arabia is a dry country, meaning no alcohol can come in, nor may one purposefully ferment things in the country. So great trouble arose when in the shipping manifest the customs officials noticed the item CLEANING ALCOHOL. With the laser cutter, Epilog ships 15 ml of isopropanol to clean the lens with. That is less than a mouthful of poisonous liquid, and will not get you drunk. However it was enough ‘alcohol’ to strand the shipment for about a week, which is approximately how long I was supposed to be in the kingdom in the first place.

Getting a visa to Saudi Arabia is also an ordeal, and after a rejected mail-in application I had to travel down to the consulate in NYC only to find out that the only people who can use the online visa application system ENJAZ are registered travel agents. So in the end it turns out I could have overnighted my passport to a random third party with no website listed on the consulate’s website, but instead I had an exciting week of intercity travel.

In Saudi Arabia, women are required to be accompanied at all times by a male escort. Generally this is a family member or husband, but in my case it was an employee of the company we were working with. Women are not allowed to drive or sit in the front seat of cars (and this was problematic for my escort because he drove a two-seater). Women also do not pray with men and do not go into mosques. But women can have jobs and it is not illegal for them to go to university.

In public, women are at all times required to be covered from head to toe. For me that meant that as soon as I got off the plane, I wore a headscarf (hijab) and long black robe (abaya). It had been ordered in advance for me in the US. It was hot, difficult to keep on correctly and somewhat restricting (I had to take smaller steps than I was used to having to do in trousers). Also, they all seemed to be made of polyester– yech.

Me in abaya + hijab, with my own addition of a tool belt, and some men in a saudi market

Most things are illegal in Saudi Arabia: movie theatres, dancing and music, and even photography is at times considered the making of icons and therefore in conflict with the Quran. However, these rules are somewhat relaxed (i.e. enforced through social norms) and in the gigantic private estates and houses, you will find everything from bowling alleys to dolby surround. Mostly it seems to me that Saudis drive around in expensive cars and stopped traffic, shop endlessly, eat american comfort food (they have every chain from Krispy Kreme to Applebee’s to Starbucks) and smoke a lot. There is a firewall keeping ‘bad parts of the internet’ out. Five times a day, everything stops for prayer time, which is around the same time for everyone in the country, and can last from ten minutes to an hour.

Anyway, this scene being set, restrictive country and no machines to assemble, I had very little to do (although one day we did go to a dinner at the vice-president’s beach house, and he served a whole goat). Luckily, earlier during my travels to NYC to figure out my visa business I dropped by Makerbot Industries home, the Botcave, and picked up a Thing-o-matic to bring to Saudi Arabia.

Yes I wore the headscarf for the entire assembly process.

Makerbot is a company making kits for low-cost-low-tech 3d printers, in the vein of the RepRap project. The printers heat and extrude plastic, as the printing head moves around on a bed to form an object. Makerbot’s kits consist of electronic components and lasercut plywood, and the ‘motherboard’ in the Thing-o-matic version is an Arduino Mega. The kit with the spindle feeder is around $1500, which is about one order of magnitude cheaper than a Dimension uPrint, which also extrudes ABS plastic (although the Dimension also can print a support material for objects with undercuts).

Stanford bunnies printed on a Makerbot. Image lifted from Thingiverse.

Makerbot was started by some of the people who once worked on the RepRap project, and also Bre Pettis, who used to work for Make Magazine, and way back in 2005 presented a drawing bot based on the MAKE: controller at the Make: Fest in Brussels. That was great conference, including reunions with fbz and her magic phone, Mark Hoekstra of Geektechnique (r.i.p. ,.,), Gijs Kruitbosch (ok not a reunion because he was in my uni class at the time), Gerv Markham, L’Arcadi food… Mark Shuttleworth gave a keynote about the then newish OS Ubuntu and also his space travels, and I perhaps had my first foray into the notions of a digital future of an internet of things that self replicates through 3-axis movement (ehm). I showed a bunch of stuffed animals with RFID readers in them.

My advisor, Neil Gershenfeld, teaches a class on building machines that can make machines– How to make something that makes (almost) anything. A lot of 3D printers come out of that class, extruding ABS, PLA, frosting, cheese, pasta, concrete, etc. but also milling machines, folding machines, shaker tables, and self-assembling folding chains. Most of the projects never go that far beyond the final class presentation where they print a heart or mill a demo circuit board. They certainly don’t start a dedicated community effort like RepRap, or Makerbot with the Thingiverse.

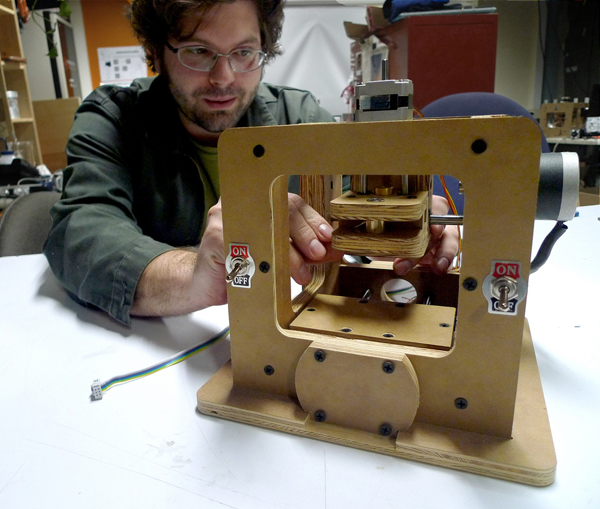

Jonathan Ward, my dear office mate, has designed maybe 5 different tabletop milling machines by now. One was made of cardboard, one was pocket-sized, some were made with his versions of legos… I swear he shows me a new kind of lead screw every week. And yet the only one who really uses his machines is him– they use control software that requires a particular brew of Linux, open frame power, and perhaps a whole pile of paraphernalia you might only find in our office.

This mini milling machine is around $200 in parts and lives in the mobile fablab Jonathan uses it to mill circuit boards.

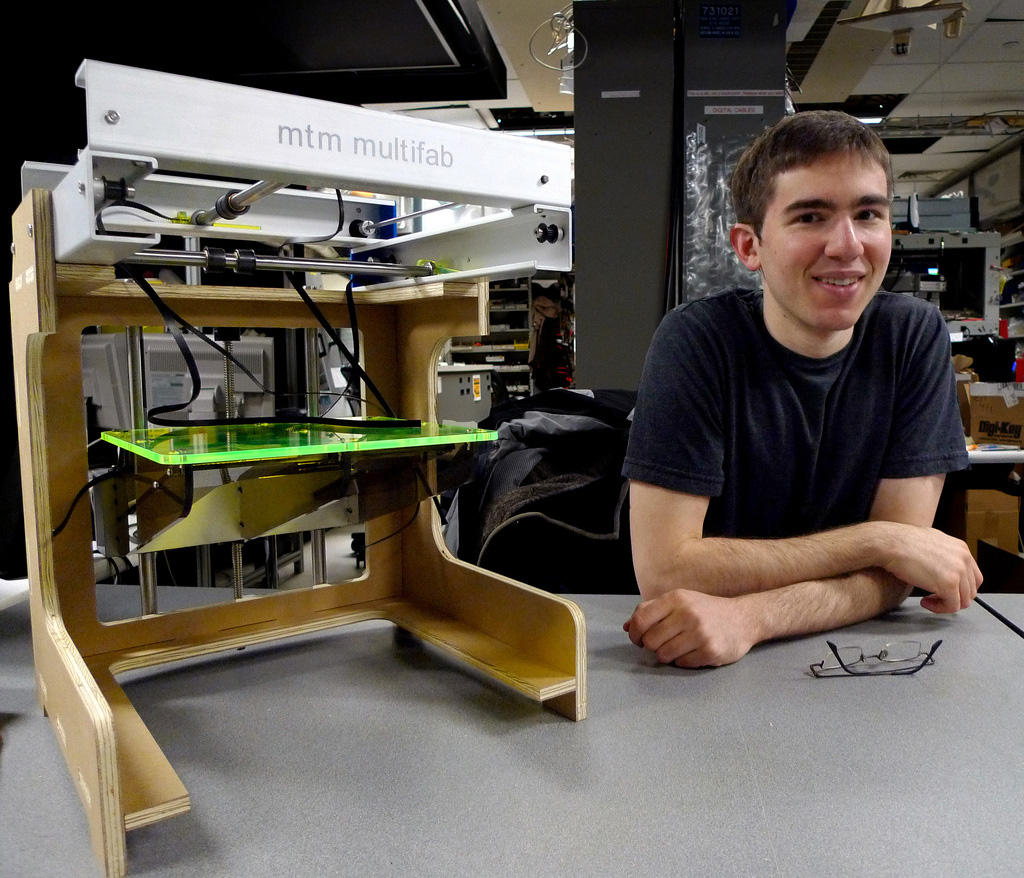

Ilan Moyer continued his HMSTMAA project into FAB-In-A-Box, a 3 axis machine with interchangable head that can 3D print, cut stickers, pipette, mill and weave. Although he started by giving away some of his machines in India, he now just builds them himself and will customise them and sell them to you, working and with instructions on how to get what you want. He found teaching and managing a community of making more Fabs-In-A-Box too much work, and doesn’t have a supply chain set up so we can ship out his machines to other fablabs. That is a little unfortunate, because Ilan has a profound understanding of materials, machines and movement, and his machines are by far the best in its kind I have seen.

Ilan’s Fab-in-a-Box blog is funny and insightful. Go forth and read more.

I’m not trying to say that people like Jonathan and Ilan (a newish faculty member at the Media Lab at some point apparently characterised their genre as ‘single white men working in their basements‘) are wasting their time. Personally though, I’m not super excited about designing precision manufacturing tools for the sake of the tool, especially not a single tool (or certainly not for the sake of the tool replicating itself), but more with an end use in mind. I don’t count ‘for everything’ as an end use. I like at least one user. So far, I’m pretty unimpressed with what you can do with homebrew 3d printers. In fact, I’m pretty unimpressed with the $30k+ 3D printers we have here at MIT. Why 3D printing? What is it for?

To some extent, I’m playing naive– I understand that there is a need for play and interaction with technologies to continue practice, design and development. That there is novelty and education! And that the mass majority of people who pick up a Makerbot or Arduino aren’t going to become designers or engineers overnight or even after a while. That tinkering is fun in and of itself.

From HTMSTMAA, brought to you by Amit Zoran: food printer concept design!

3D printers remain the poster child of the desktop revolution where we can print anything instantly. The future. Although I’m positioned in a place where it would be logical for me to hurtle towards this future of anything you want, instantly, I instead spend a lot of time thinking about what I want, and what I think other people may want. One thing I want is it to be easier to design things I want– not a better 3d CAD program, but many more modular and useful abstractions that let me connect things together easily. Why do I still have to write assembly to connect a screen to an input device? Why doesn’t a GPS module ship with its dimensions in something more useful than a PDF datasheet? Why can I buy a cell phone for less that $10 but not make one for less than $300?

These thoughts were bouncing around during my 2 days of Thing-o-matic assembly, and also things like ‘metal nuts and crappy plywood t-slot assembly!? look at all this play! it’ll be unmanageable in 2 days of Saudi humidity!’ or ‘couldn’t they have spend $.40 more and gotten a motor I didn’t have to disassemble and realign?’. In the end, there was some problem with the ‘motherboard’ and somehow the z-axis hard stop was shorting out the board, and I was moving things around in the control code to not have to use that part of the motherboard when the rest of the fablab equipment showed up. Now I know it takes about the same amount of time to assemble a Thing-o-matic as it does to assemble the rest of the machines in the fablab (4×8 foot milling machine, laser cutter, vinyl cutter and mini milling machine).

Hopefully now with all these fabrication machines in Jeddah, some target audience who wants to use them will show up. The fablab has separate male and female opening times, which at first I thought was ridiculous, and later realized was necessary. And what do I know, maybe the lab in Jeddah, with low-cost 3D printer and plenty of funding, will spearhead into a future of empowerment.