Maker to Manufacturer: White House Nation of Makers Event

June 21st, 2016Tags: digital fabrication, infrastructure, maker to manufacturer, nation of makers, ostp, white house

I’m sharing my slides from a presentation I gave today at an Office of Science and Technology Policy organised event From Maker to Manufacturer.

This was part of the White House’s Making week: https://www.whitehouse.gov/nation-of-makers

Hi, I’m Nadya Peek at the MIT Center for Bits and Atoms.

Right now we’re covened to discuss how to go from being a maker to being a manufacturer. An obvious way to do this is to provide Design for Manufacturing education– to accellerate the process of going from product to prototype and scale makers. But let me ask the obverse. What if it’s not the makers who need to learn about manufacturing, but manufacturing that needs to adapt to makers? What if it’s not Design for Manufacturing, but Designing Manufacturing for making?

As we went from mainframes to personal computers, we lost no precision or accuracy. The same calculation gives the same answer on any computer, some might just be faster than others.

But after we first got the precision of digital fabrication by hooked up a milling machine to a computer, we did not create a similar universal infrastructure in the home for fabrication. The machines you encounter in fablabs and makerspaces cannot make products of the same precision and complexity as industrial manufacturing. Why not? Why don’t we have the equivalent of the internet but for manufacturing?

From my point of view, infrastructure for manufacturing is pretty broken.

When I was at NASA, I noticed that the milling machine they used was the same one as was first hooked up to a digital computer! The difference is now it runs windows xp.

At MIT we students can’t easily use tools like robot arms because their languages are proprietary and buggy. Their interfaces are anything but seamless.

I spend lots of time drinking Baiju with factory owners in Shenzhen because I need to source parts locally without quality fade. That’s not a scalable model for supply chain!

Not to mention that the current intellectual property landscape is chilling for small-scale developers!

Digital fabrication provides precision, but at the moment it’s still optimized for mass manufacturing– making the same macbook enclosure over and over. That’s not the low volume world that makers can work in.

How do we make maker-friendly manufacturing infrastructure?

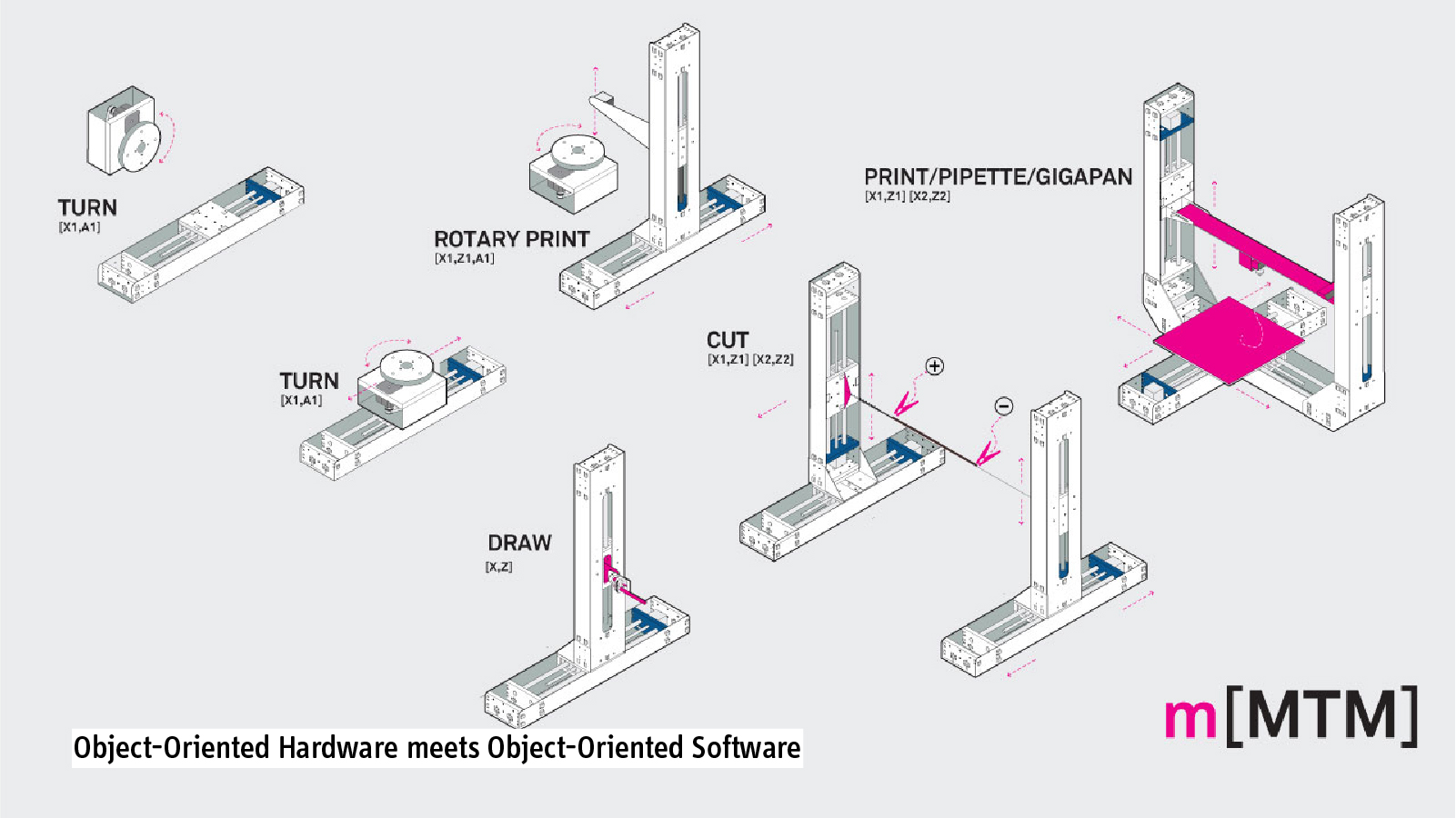

I taught a class on machine building at MIT, and I noticed that it was very hard for students to do full stack system integration. They made all these machines, 3d printers, wire EDMs, 6 axis hot wire cutters, but it was a semester long endeavour. So what if they needed a specific machine? Why can’t that rapidly be prototyped? Why can’t we have rapid prototyping of rapid prototyping machines?

So at MIT, I haven developing modular software, firmware, and hardware under the paradigm Object-Oriented Hardware. Borrowing from the concepts behind Object-Oriented programming, I’m creating infrastructure for rapid machine building so that we can start changing manufacturing to match makers.

These tools we developed were used by hundreds of digital fabrication students to build machines out of these cardboard machine monomers. These infrastructures led to novice makers building 5 axis machines without issue. If rapid prototyping of rapid prototyping machines can lead us to rapid automation, that can start manufacturers changing to match makers. This is only one example of how we can start chaging manufacturing though.

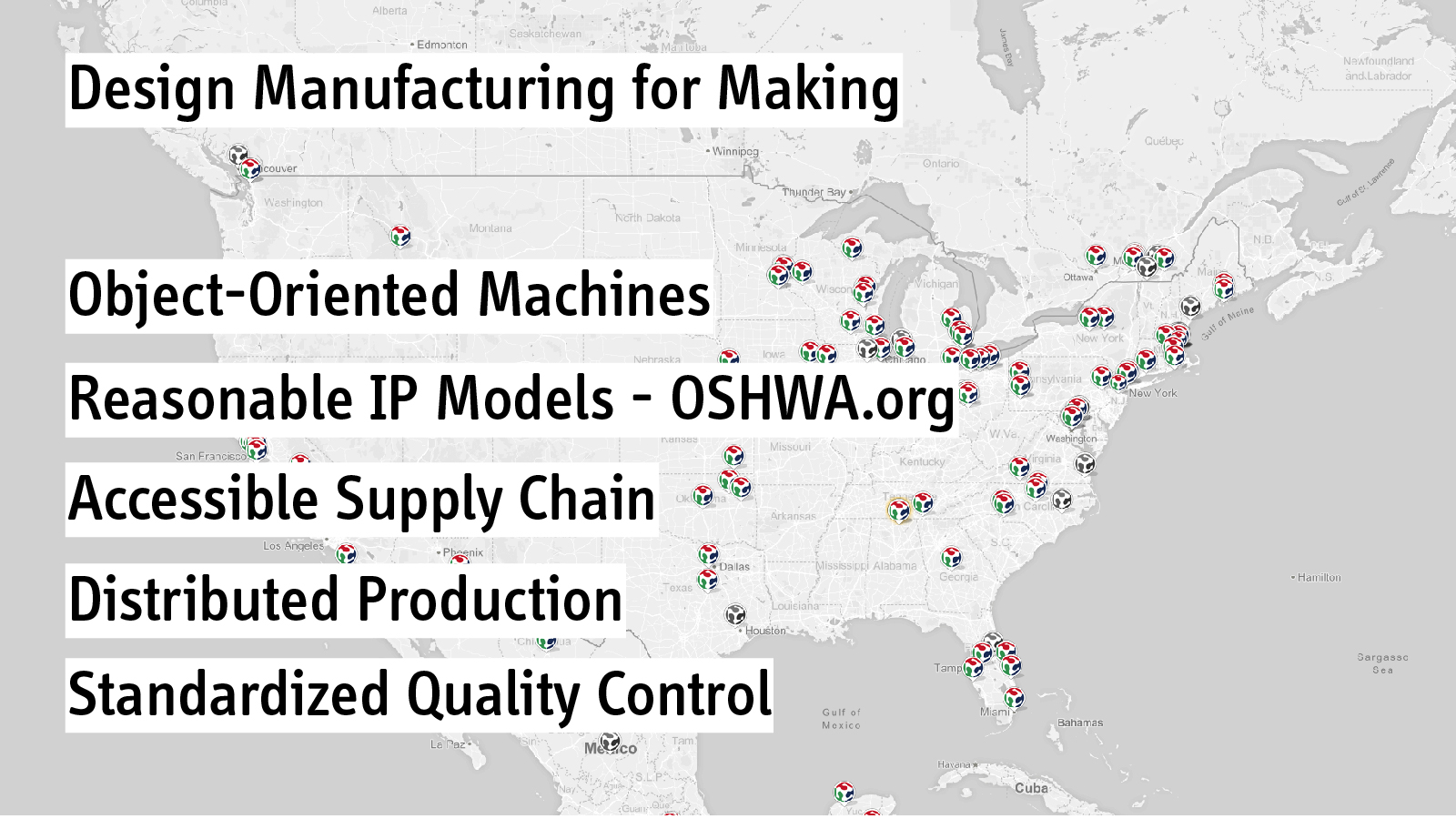

If I had a magical press release I could issue and it would then be true, it say

Federal agencies are deploying standards for rapid automation: modular machines and object oriented hardware,

We now have widespread patent reform,

We have standardized ways of dealing with supply chain, distributed production, and quality control, such that not every entrepreneur needs to reinvent those wheels.

Infrastructure is hard– I don’t think that a 3d printer on every child’s desk is going to revolutionize manufacturing. I also don’t think we need to onshore all those manufacturing jobs that were offshored. But this network society needs a manufacturing infrastructure that is networked too, from the home level, to the library, to the town hall, to the state, to the nation. So in the discussion, I’d love to talk about how we’re going to design manufacturing for making.