Molding and casting

December 2nd, 2008Tags: fabclass, fablab, how to make almost anything, htmaa

Week 11: design a mold and cast a part.

I have had a stovetop espresso maker for about 10 years now, and the rubber gasket that seals the top and bottom parts together has seen better days. Somehow the part is not a standard cafetiere gasket, it has a lip that covers the sieve, so even special searches in italy would come to no avail.

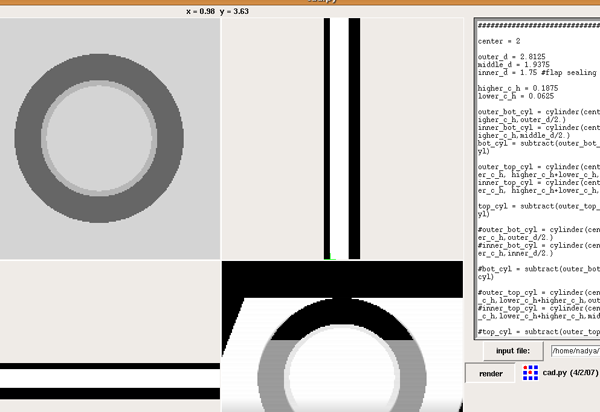

I decided to design my part in cad.py, because it was a simple enough shape that it would probably work out very well. And indeed, it did. The part consists of 2 cilinders added to each other, and the mold is a block with its top at z=0, with the gasket subtracted from the top. If you have the view of cad.py set in such a way that the edges of the block of you mold outside the view of cad, the contouring/milling will only be done on the part itself.

One problem I encountered was that calculating the contours for my part would take a very long time at 250 dpi, which is what I set for the machining. After the contours would be calculated, cad.py would output an .rml file but also crash. To be able to still send the .rml file to the modela, you can use the following command in a terminal: cat /out.rml/ > /dev/ttyS0/

where out.rml is the file location and /dev/ttyS0 is the serial port that the modela is on.

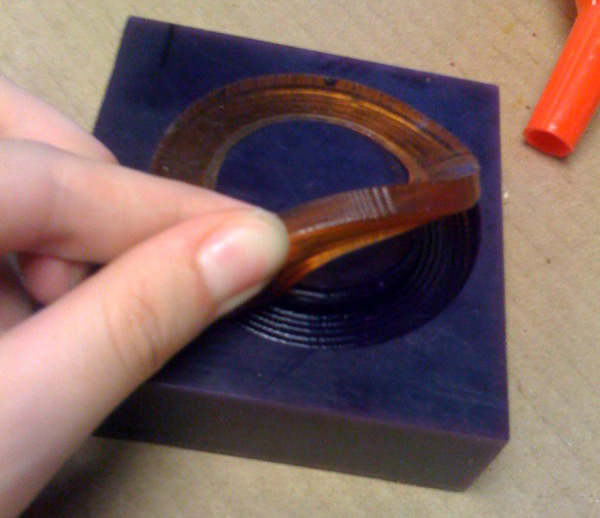

I first cast a test part in the urethane to see if it would fit in the cafetiere, but to be able to cast a part that can actually be used I should go with an FDA approved material that can withstand high temperatures. After some googling on the smooth-on site, I found that Smooth-Sil 940 is FDA approved up to 270 degrees celsius and is generally used as a candy or chocolate mold. I also talked to a distributor and found that the other Smooth-sils have similar material properties but did not go through the FDA approval bureaucracy, but are probably safe enough to use in foodcasting.