Disregard that particular flavour

April 16th, 2014Tags: akiba, bunnie, china, David Cranor, david mellis, fablab, huaqiangbei, human, jie qi, manufacturing, mellisphone, Nan-wei Gong, open source hardware, shanzhai, shenzhen, technoghetto

On cell phones, open source hardware, Shenzhen, Shanzhai, manufacturing, and disregarding technological solecism

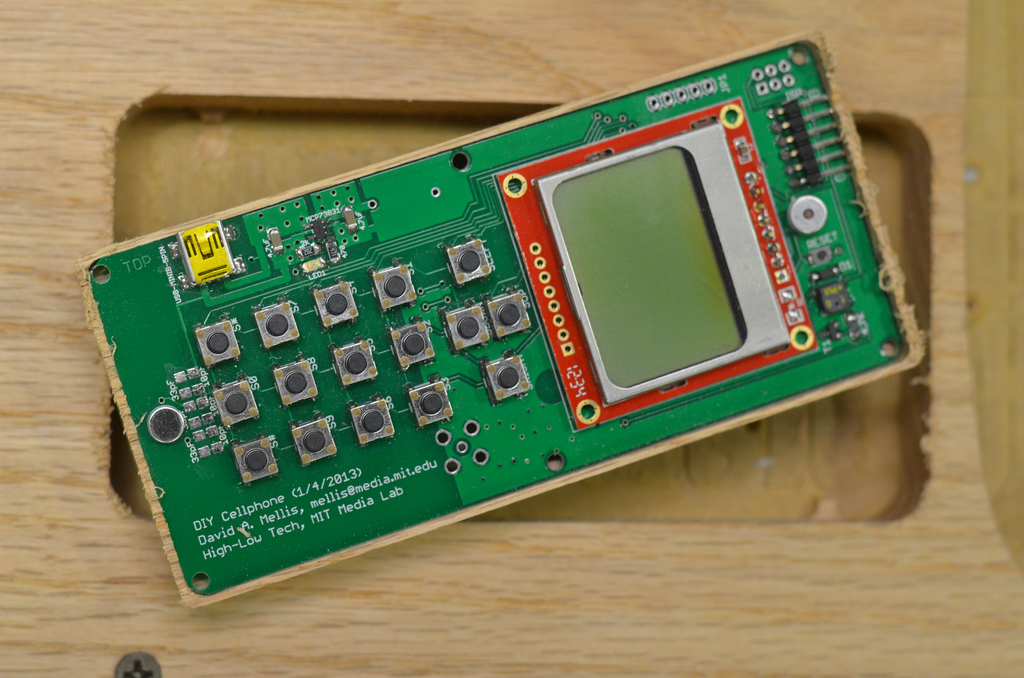

More than a year ago, I stuffed one of David Mellis’ open source cellphone boards, and started milling a custom oak case for it.

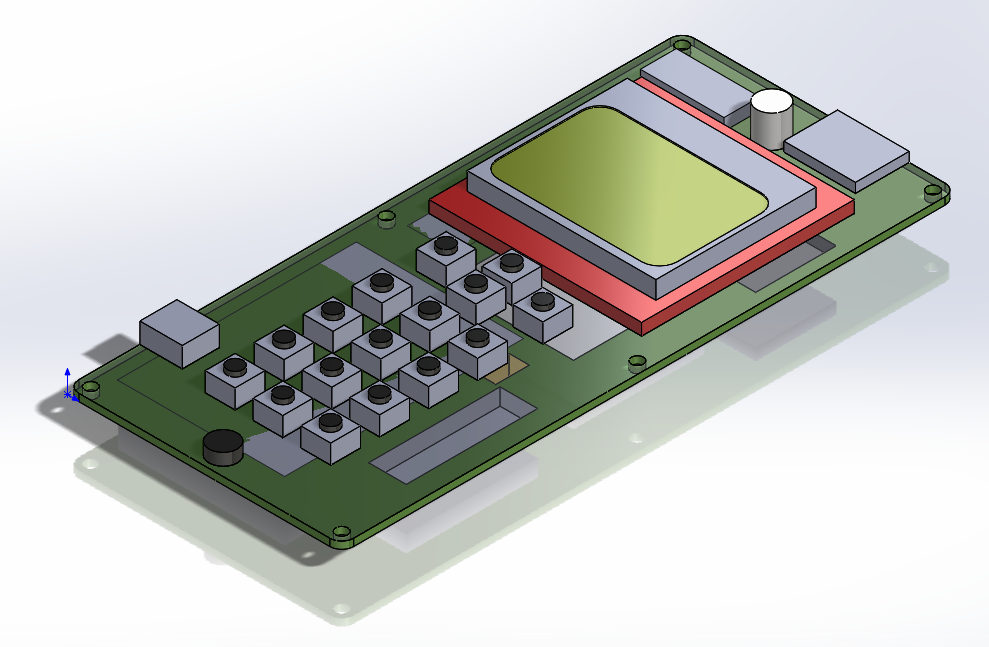

I made an excessive model for it, which is now outdated because I have the older version of the screen, but you can download it here, maybe you can use it. I was in India, and bored, and I’d brought a really nice pair of calipers. Here’s a partworks toolpath for a case too. Wouldn’t it be nice if open source circuit design software made 3d models?

Open source hardware cell phone case production using the shopbot.

The Mellisphone1 is large, so far only has the features call and text, and doesn’t connect to the AT&T network in the Bermuda triangle of communication instrumentation that makes up my street. However, as a project it represents a much more thrilling intention, one where the educational techno-intro projects that you can tackle in garages and maker spaces and fablabs start cross breeding with the products and tools that you actually use on a daily basis.

Personal fabrication appeals to me because I generally feel that my preferences are unrepresented by the product options that are available in the marketplace, and personal fabrication encourages developing alternatives. Digital fabrication tools enable this to some extent, offering tools you can make things with without needing much skill or craftsmanship in the traditional sense. I like victories of small design efforts over products born from giant military industrial complexes, but I know of few examples. Sometimes dissenting technology just follows a tech-vigilante-grows-up-and-becomes-their-own-massive-empire story, or worse, a more prevalent tech-vigilante-is-punk-but-finally-concedes-to-acquisition-by-sensible-grownups story (see perhaps Apple for the former and Makerbot for the latter). Reasons for the lack of examples could be that many ideas are marred by an overly romanticised and simplified view of manufacturing ecosystems and what it takes to get things done, and fail (see for example the New Yorker critique on the Global Village Construction Set), or because the successes are by definition small and therefore not on your radar (see for example De Laet and Mol’s analysis of the Zimbabwe bush pump as appropriate technology).

I am (perhaps unfairly) not considering speculative and critical design, even though an evocative narrative is perhaps even better than an actual product when what you’re aiming for is questioning the status quo. Criticism is sometimes its own ivory tower.

Artifacts have politics, and I hope personal fabrication enables dissenting views. I might not use my Mellisphone as my primary telephone, but I will keep working on a technological landscape where that kind of production becomes a reasonable alternative.

…

Then last week I (and other cats) found myself lost in the cell phone recycle repair and repurpose microcosm that is Huaqiangbei in Shenzhen2. People like Mellis and I lead a charmed existence where we have access to fabrication equipment and tools even though we live in a country where that kind of labour has largely been abstracted away, and so we don’t necessarily have to go through the techno-fetish re-infatuation stage with advanced manufacturing techniques that can characterise the “bring jobs back to AMERICA” discourse3. However, it’s still fascinating to watch the consumer goods economies of scale create a technoghetto remixing ecosystem like Huaqiangbei. The ambivalence there towards design, technological features, original versus aftermarket parts, branding, intellectual property, et cetera, really blurs the categorisation that is easy to assume is strict once everything is packaged up, unmodifiable, and for sale in, say, the sterility of Best Buy.

These aren’t even recycled ICs, there is no solder on them. The ones I learned about were between 1 and 10 rmb each.

Why do they even have empty phone motherboards? What channels do these show up at this marketplace through?

Here’s bunnie buying ICs for the iphone 5, he also just bought an unstuffed motherboard for 50 rmb. He’s going to learn to solder them on the next day, and in lieu of a blow-by-blow I’ll at least say materials involved were dried out solder paste, toilet paper, and a wood screw.

I try hard not to be a nerd-stuff-hoarder, because I try not to conflate buying project-less-parts with project-engineering (because then you just end up with an apartment full of guilt) (not that anyone who has ever been in my officelair would attest that I’m good at this), and I try (a little at least) to make reproducible projects, so I didn’t come home with a suitcase of random acccelerometers and laser diodes even though they were enticing (but I apparently do not try to avoid parantheses). Also, hearing about fbz divest of material possessions earlier this year was sobering. However (after all these consumer-guilt disclaimers), I did bring home this tiny Shanzhai iphone clone:

mommy can I have a puppy

Hellooo this shit is hilarious. Will’s iphone here too for comparison.

So for 150 rmb you get a weird home-rolled design-derivative OS that includes ‘apps’ for QQ and Baidu, a resistive touchscreen, two batteries, a camera, an mp3 player, headphones, user-accessible memory card slot, and a real conversation starter. How many person-hours of development time went into the OS on this phone? How ingenious were they about saving memory so they could save money? Who went to work in the morning and thought how about an iOS simulacrum?? Who then went to work for many more mornings and implemented it?

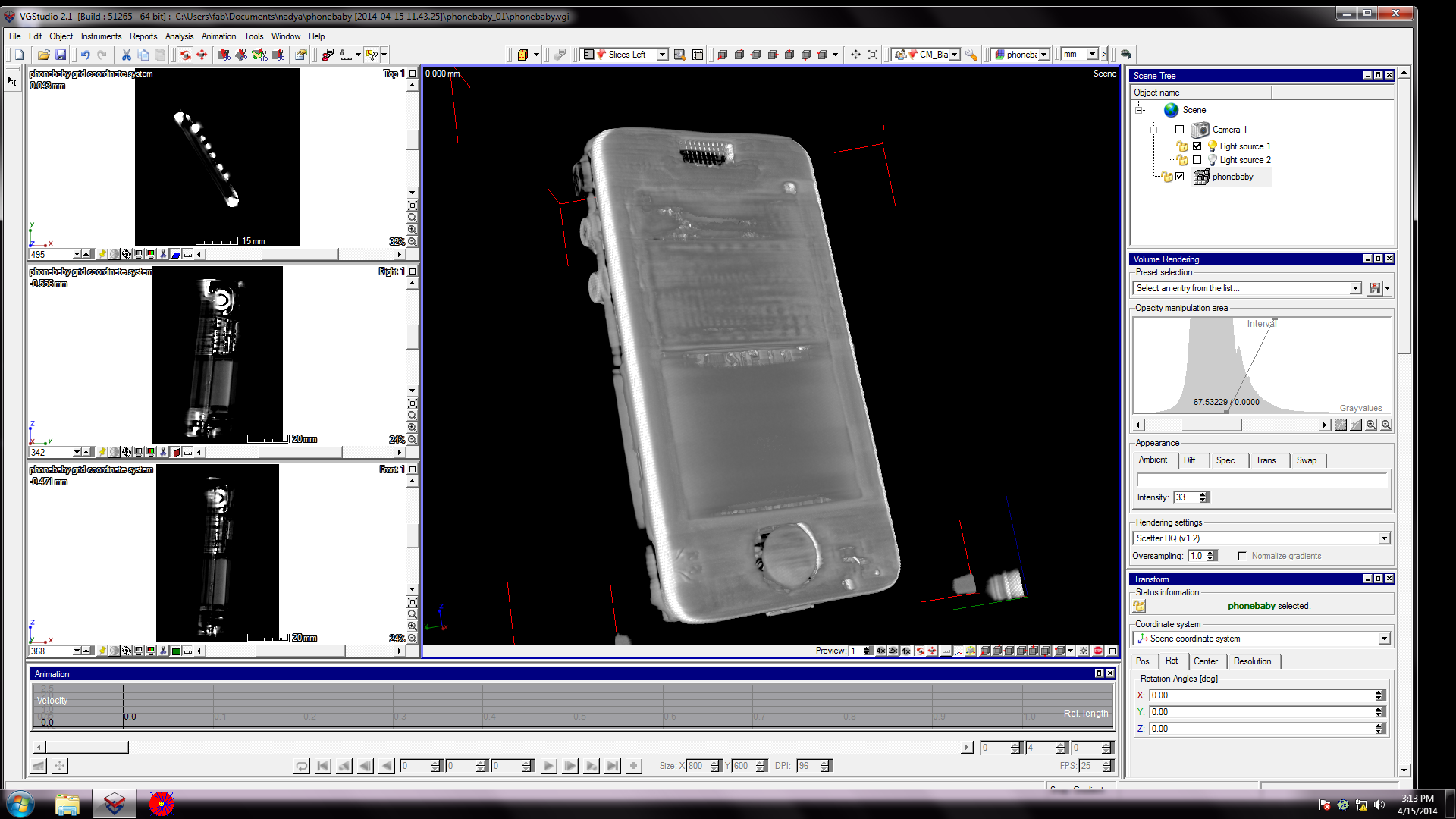

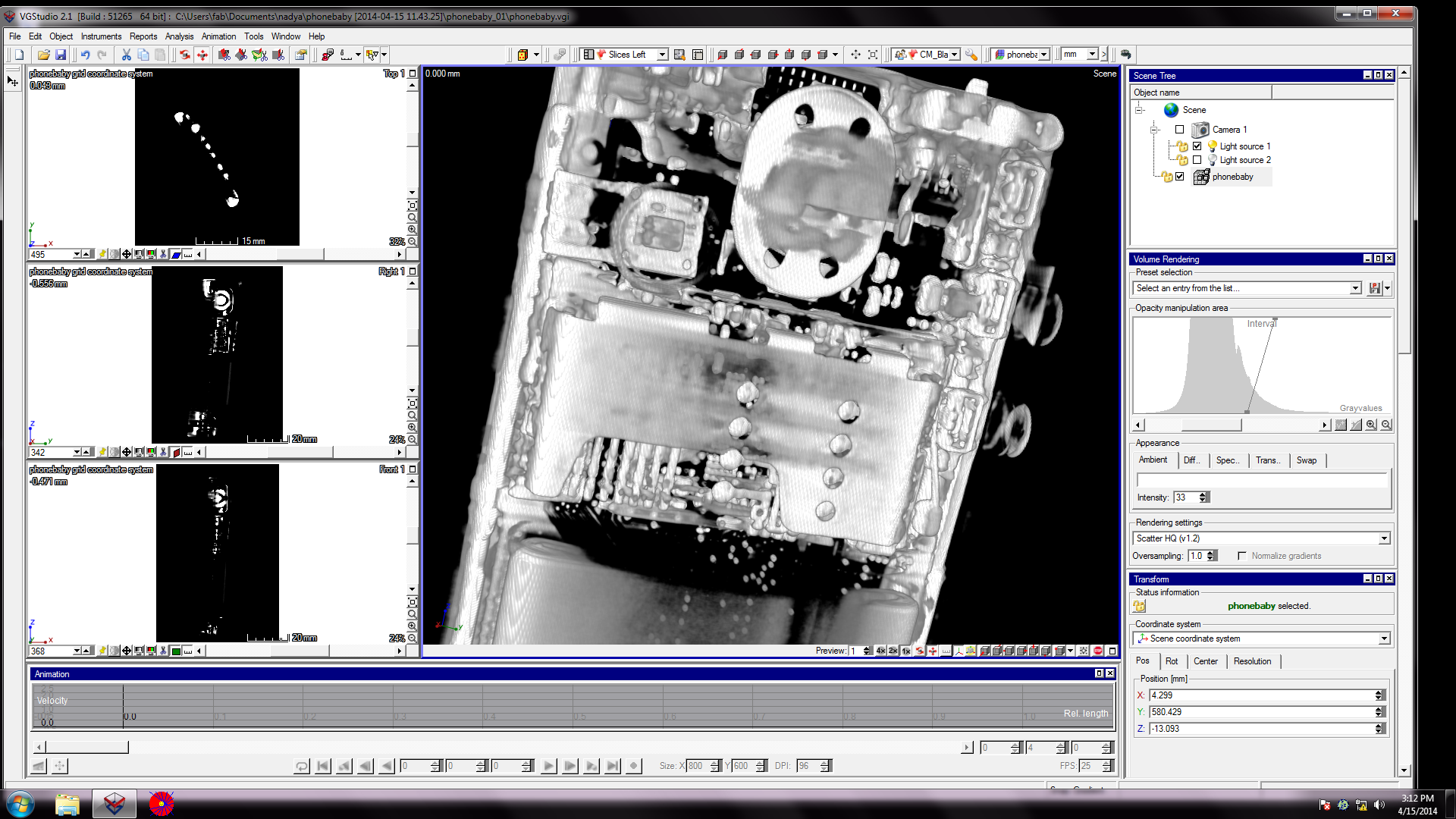

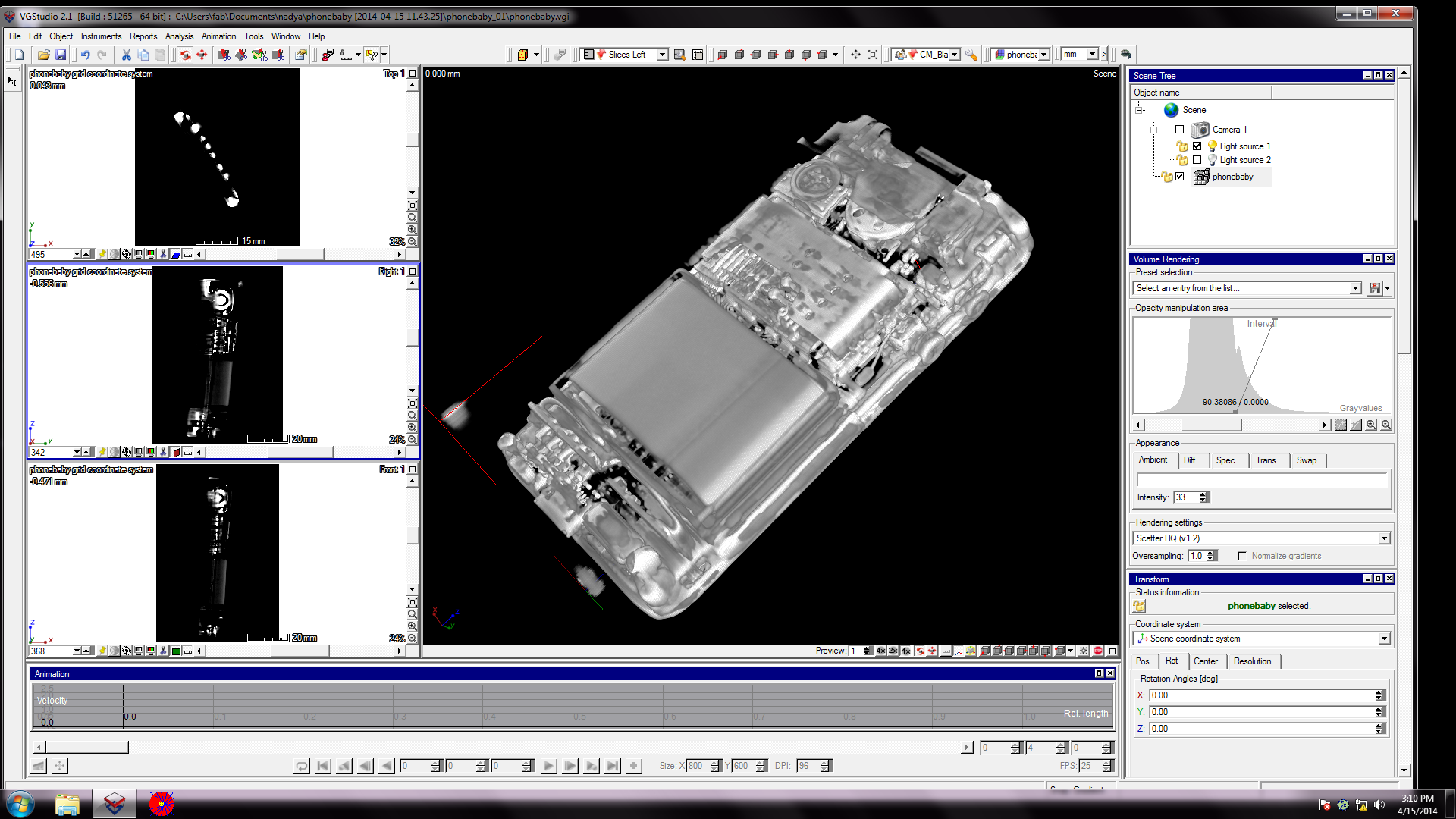

Yeah I x-rayed it but learned little about its origins

Under the auspices of pics or it didn’t happen I present also a CT scan of the phonebaby, also known as the Melrose Terminator X (lol). Not that it wouldn’t have taken me much less time to take the whole thing apart. (Here’s bunnie doing that to a different phone from the same marketplace.) It has a little PCB sandwiched on top of another PCB, which I for some reason quite enjoy.

I like this object is so many ways- its smallness (in form factor and target market), its referential design, the crippled appification of its file system, the anonymity of the people who made it, how it’s easier to take apart than an actual iphone (and you can e.g. put a memory card in it)… I haven’t ever found myself liking a cell phone before, I just think of them all as obnoxious but required communication tools. (Not that this phonebaby thing has a pleasant UX either.)

Searching for the phone online, I can’t immediately find a photo of the model I have (the Melrose Terminator X). Who made it? For whom? Where?

In a recent talk Joi Ito talked about this cell phone market as a space where “kids” in Shenzhen are remixing hardware to make new kinds of technology and innovation. Cell phones like this one are perhaps what he is discussing, but from what I observed their design and production aren’t anchored in technological cross breeding and innovation, but instead in an attempt to create the desirements of a covetable-enough cell phone in the necessarily creative space of extreme low cost. What you end up with is a very funny self-referential tackiness.

Cranor bought a PROSHCE cellphone

What a boss (even though the thing was janky enough that its usb didn’t seem to be connected to the charging circuit, and so after depleting the battery the first time Cranor was immediately invited to do some “remixing” of his own).

…

Meanwhile, we decided to go to the Shenzhen Maker Faire. The maker faire franchise’s extension to countries where “making” is still a major part of the population’s livelihoods perhaps deserves a post of its own, but maybe I’ll get to that another time. I like to complain that Maker faire is really more like buyer faire, with booth after booth of vendors in something that seems like a “my first trade show”, and the first question out of the visitor’s mouths often being “how much does it cost?”. Shenzhen Maker faire was similar (if not more so because of the loose interpretation of what constitutes a derivative design), but I also ran into a globalised crew of maker-friends I’ve met in Amsterdam, Detroit, Lima, et cetera, making it hard for me to claim that I didn’t feel at home.

And then, amongst all the other booths, we spotted a Mellisphone:

Unlike lazy people like me, Mellis actually has been using his Mellisphone as his primary cell phone for years. Here he is with his and theirs.

The people manning the booth had taken the design, replaced the parts that were hard or expensive to get in China with local alternatives, translated the instructions into Chinese, and were encouraging visitors of Maker Faire Shenzhen to make their own cell phones. Sure, one cab ride away there was a whole marketplace of people doing exactly that, but those societies are still disjoint. The people designing cellphones in Huaqiangbei aren’t the students presenting at Maker faire- they represent very different social strata with very different design intentions. One is responding to a fluid market by supplying products, and the other is learning about manufacturing and production while questioning the technology people are taking for granted in their pockets.

Yes, the “maker movement” can be a self-congratulatory exercise in “making” for the affluent (see also Morozov’s critique). Yes, I also find that problematic. However, the beginning needs to be somewhere, and being dismissive of artefacts that attempt to start this discourse (like the Mellisphone) is counterproductive if the end goal is exploring whether tools and technologies can be produced personally, instead of being mainly controlled by large corporations and institutions (even if they’re “not evil”). The possibility to make your own technology might have been there all along, but sometimes you also need to be invited in.

I’m seeing the cavalier and casual Shanzhai manufacturer and the unencumbered maker (empowered by low manufacturing cost and more transparent production models) converging, and you can count on my being at that party too.

Finally, in their own jugaad innovation, here’s the inimitable Akiba someone on shippers row in Huaqiangbei mailing out lithium ion batteries in individual cardboard boxes so that they appear like cell phones to customs and make it through:

Hee hee hee.

1. Mellis doesn’t call the mellisphone the mellisphone, but let’s all agree right now it’s the best name for it. <

2. Because I do not use facebook, twitter, or even that much google (because ddg is not blocked in china after all!), I noticed very little of the great firewall except that vimeo and youtube are both blocked and I don’t host my own videos. If anyone has the ideal easy solution to this I’d love to hear about it, as blip.tv also recently decided that I am not a real TV show and deleted all my videos. Actually I’m pretty sure vimeo lost all my videos from before 2008 too, so fuck internet services, they suck. <

3. I guess there is a line of reasoning where you can argue that CNC tools, CAD software, and less-retarded CAM allow manufacturing to come back to the US, and all we’d need is unscripted digital literacy that takes no time whatsoever. But that’s a different post. <

And a final floating footnote: title is in reference to the William Gibson essay collection Distrust that particular flavor (of italics) which in turn references the essay Time Machine Cuba which includes this quote: “They are the italics of the perpetually impatient and somehow perpetually unworldly futurist, seeing his model going terminally wrong in the hands of the less clever, the less evolved.” Like Joi said, whatever futurists, let’s be nowists. Speculate all you want, I’m in lab. Thanks to Sophia for the recommendation.